Toyota has revised its global production forecasts by 100,000 units for the month of May after confirming a number of production line suspensions.

Toyota says that component shortages from Covid-19-related supply chain constraints has caused “considerable inconvenience” to its customers, suppliers and previous production forecasts, and is temporarily suspending production at a number of its plants.

Toyota is labelling the suspensions as an “intentional pause” that will allow it to stockpile more vital components, in the hope it can kick-start full scale production later in the year.

For now, Toyota has said that production for May will be around 750,000 units; 550,000 of which are for export around the globe, while 200,000 are for the Japanese market, which is down by 100,000 units.

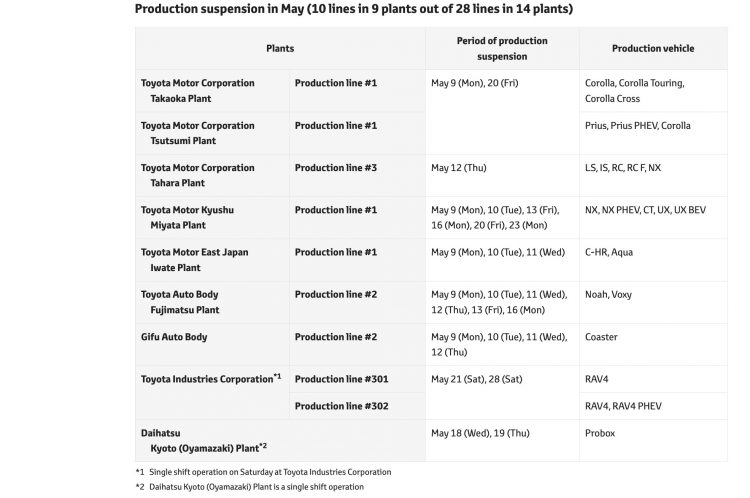

Toyota says that global production numbers in July are expected to rise to 800,000 units. All up, 10 production lines across 9 plants will be suspended in May, out of a total of 28 lines across 14 plants.

Production vehicles implicated in the temporary shutdown include the Corolla, Corolla Cross and Touring, the Toyota Prius, C-HR, RAV4, as well as the Lexus UX, NX, LS, IS, RC and some Japanese-market variants.

Meanwhile, Toyota is also making news after announcing a US$383 million investment in its US production lines, focusing the majority of funds into four-cylinder engines and hybrid powertrain production.

Of that figure, $222 million is slated for its Huntsville, Alabama factory to create a new production line for four-cylinder powertrains, including hybrid variants, while Troy, Missouri will receive $109 million to scale-up production of three-million cylinder heads each year.

Toyota’s VP of manufacturing and engineering, Norm Bafunno, said: “Toyota customers want vehicles that are fuel-efficient and electrified. These investments allow us to meet customer needs and quickly respond to an evolving market.”