Toyota has once again been forced to adjust its production schedule, with the world’s largest automaker apologising for the repeated adjustments amid parts shortages.

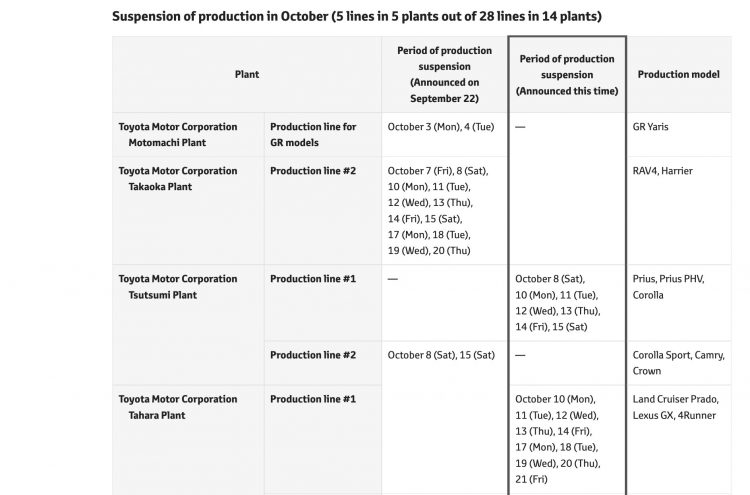

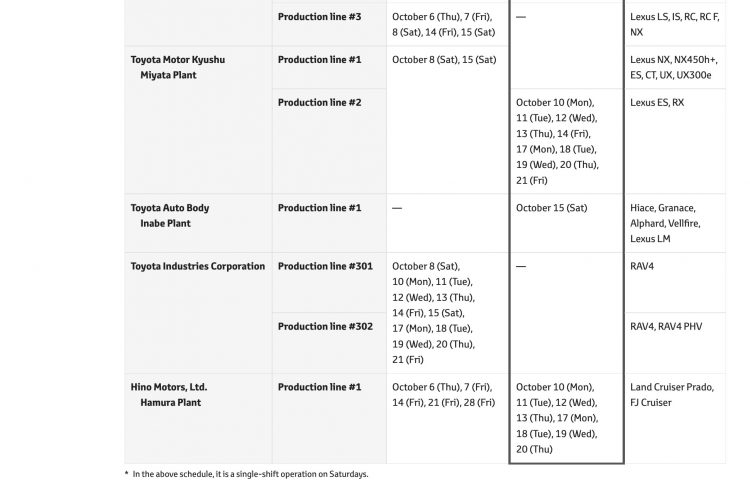

The most recent change to Toyota’s production schedule involves five production lines across five manufacturing plants, out of a total of 28 lines in 14 plants.

The most lengthy production suspension involves a pair of 12-day shutdowns for two major production lines that assemble the Corolla and Prius, as well as the LandCruiser Prado and Lexus GX twin, and the Lexus ES and RX.

The company has apologised for the repeated adjustments, blaming the “parts shortage from the spread of COVID-19″ for the “considerable inconvenience” caused to its customers.

All up, Toyota says that its choice to suspend factory floors through the month of October will reduce its production volume by 50,000 units, which will reduce Toyota’s production for the month from the estimated 800,000 units to 750,000.

So far this year we’ve seen Toyota suspend a number of production lines to stagger production in June, and again in August where Toyota shaved its production estimates by 150,000 units.

In spite of the numerous production suspensions, Toyota says that its production forecast for the entirety of the fiscal year remains unchanged at 9.7 million units.