Hyundai and Kia have detailed an innovative new electric drive system that they say will allow future vehicles to put their power down more efficiently on bumpy surfaces and greatly transform space and practicality thanks to the super space-efficient packaging.

It’s called the Universal Wheel Drive System, or Uni Wheel for short, and in short, it does away with the conventional drivetrain design and instead packs the CV joint, driveshaft and reducer into a neat little package sitting inside the wheel. The electric motor is effectively split into smaller segments and moved into the wheel, too, hence the name the uniwheel.

The electric motor is effectively split into smaller segments and moved into the wheel, too, hence the name the uniwheel.

Look a little closer and the new design takes power produced by the electric motor and transmits this via a ‘sungear’ to a set of pinion gears, which are mounted inside the large, circular ring gear that gets to work turning the wheel.

To handle the bumps, the link between the e-motor and driveshaft to the unigear assembly is able to rise and fall as the suspension travels up and down on road irregularities. Hyundai and Kia say that one of the key advantages of the system, other than the space and packaging benefits is that it can move freely while putting down its power regardless of road conditions.

Hyundai and Kia say that one of the key advantages of the system, other than the space and packaging benefits is that it can move freely while putting down its power regardless of road conditions.

In a typical CV-jointed driveshaft, power and torque produced by an electric motor can drop in efficiency as the angle of the wheel changes on rougher surfaces.

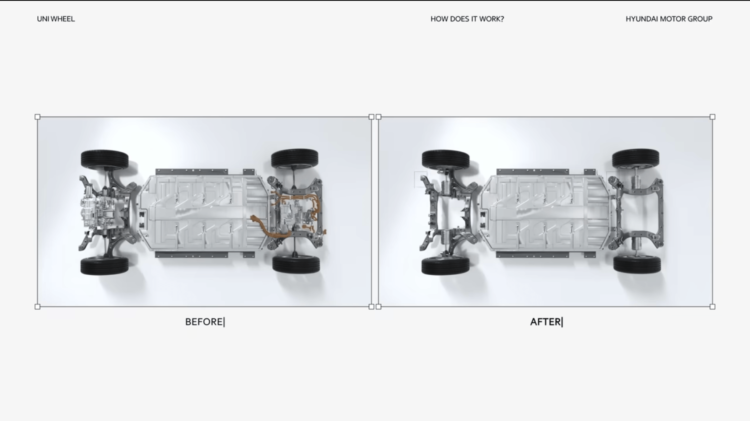

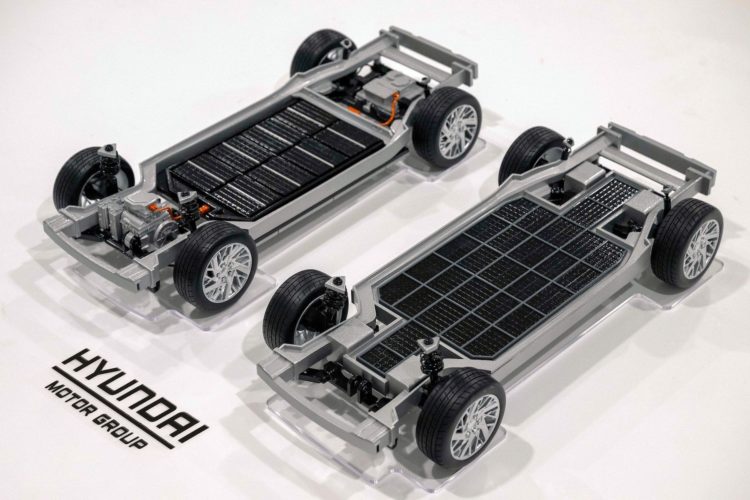

There is also the opportunity to utilise the now-vacant real estate on the platform that could be filled with larger battery packs, helping to increase range figures for future battery-electric Hyundai and Kia vehicles that pick up the Uni Wheel design. It will also give features like all-wheel torque vectoring systems more responsiveness on the road, while its modular design means it can be scaled-up from smaller wheel sizes for A and B cars all the way up to flagship SUVs and people-movers.

It will also give features like all-wheel torque vectoring systems more responsiveness on the road, while its modular design means it can be scaled-up from smaller wheel sizes for A and B cars all the way up to flagship SUVs and people-movers.

Engineers say they’re still going through the motions testing its longevity over time and punishment on undulated road surfaces, as well as retuning the gear ratio of the pinion gears.

So far, it’s passed the first series of performance requirement tests, including runs up to 120km/h and maximum wheel torque figures of 1200Nm. Looking forward, Hyundai and Kia have not put a timeline on its roll-out, though says that eight patent for the Uni Wheel have been submitted in South Korea, the United State and Europe.

Looking forward, Hyundai and Kia have not put a timeline on its roll-out, though says that eight patent for the Uni Wheel have been submitted in South Korea, the United State and Europe.

“We are pleased to showcase innovative ideas that could become game changers in the future mobility market,” says Jongsool Park, Senior Fellow at the IATD of Hyundai Motor Group.

“We will perfect the technology so that customers can experience mobility in a completely different and new way,” he added.