Direct injection is becoming an increasingly popular technology within the automotive industry, but what is direct injection exactly? How long has it been around and what cars is it available on? And, more importantly, is it any good? That’s what we’re here to find out.

Despite Volkswagen and Audi marketing the term perhaps the strongest out of all manufacturers, direct injection was first invented in 1925 on the Hesselman engine invented by Jonas Hesselman in Sweden. Since then, various manufacturers and fuel system companies have pioneered and revolutionised the same basic design.

In 1996, Mitsubishi kicked off the more modern designs with the Mitsubishi GDI (Gasoline Direct Injection) system. This was the first of such systems to ever come out of Japan and it was available on the Mitsubishi Galant 4G93 1.8-litre four-cylinder petrol engine.

In 2000, Volkswagen kicked off its FSI (‘Fuel Stratified Injection’) technology which was first available on the Volkswagen Lupo 1.4-litre four-cylinder petrol engine. Volkswagen already had access to plenty of research and development, as Audi had been running various types with its Le Mans series racing cars for years.

A range of other manufacturers have also developed their own systems, such as General Motors’ GDi – which also brought out the first mainstream production car with direct injection in the US in 2004. BMW has its High Precision Injection (HPI) and Mazda has its Direct Injection Spark Ignition (DISI). Ford also came into swing with its range of direct injection setups in 2007 with the launch of EcoBoost engine, using Gasoline Turbocharged Direct Injection (GTDI).

No matter what manufacturer came up with it first, or which system is regarded as best, all of them showcase the same basic principle.

In a conventional fuel injected car, i.e. most post-1986 model vehicles, the engine uses injectors which spray fuel vapour from a common rail of fuel. This rail is simply filled and pressurised with fuel by a small line or pipe which leads from the fuel tank and fuel pump.

The conventional design sprays fuel vapour into the inlet manifold where it is blended with induction air. The blended mixture of fuel and air is then sucked into the combustion chamber as the inlet valves open for each cylinder, according to the firing order (check the basic diagram above). So, metaphorically speaking, fuel is sprayed into the ‘foyer’ where it is mixed with air, and when the party is ready to start, the main door opens and the mixture is pulled in.

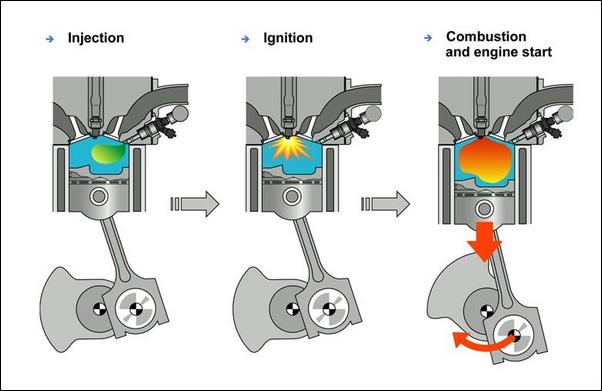

With direct injection, the fuel is simply sprayed straight into the combustion chamber, or the ‘party’ room, while the air is sucked in as usual. Each injector is tapped right into the head of the engine, much like a spark plug. The locality of the injector in regards to the combustion chamber does vary between different manufacturer designs. Some have the injector tapped directly on top, while others place it further down, into the side of the chamber, like the diagram below.

This design allows the engine’s computer to calculate much more precisely how much fuel is needed for each combustion. The direction of the injector also allows for a more efficient spray pattern providing a more complete ignition of each stroke.

It may sound fairly simple and obvious but the technology helps the engine to run much more efficiently, consuming less fuel. The system also increases the horsepower of the engine since each ignition is more complete and maximum energy is obtained from each cylinder.

A simple example of this can be found with the American Cadillac CTS which comes out with a 3.6-litre V6 engine, both with and without direct injection. The normal indirect engine offers 196kW (263hp) while the direct version offers 227kW (304hp). Meanwhile, fuel consumption ratings are 13.8L/100km vs 13L/100km (indirect vs direct).

One of the other main advantages of the direct injection system is that idle is not achieved solely via the restriction of the throttle butterfly, instead, direct injection sprays only enough fuel into the combustion chamber as required, electronically, to maintain idle and keep the engine running. This helps to reduce fuel consumption.

So to answer the initial question, is it any good? Yes. It’s a much more efficient method of feeding the engine with air and fuel. The only downside to the technology is that it is generally more expensive to develop. This is due to the design of the injectors. Each injector needs to be made to withstand the extremely high pressures of combustion. The injector is also exposed to ignition, which means it needs to be made from significantly more durable and robust materials.

Direct injection isn’t only available on expensive European sports cars though, our local Holden Commodore 3.0-litre SIDI and 3.6-litre SIDI (Spark Ignition Direct Injection) engines have it, as does the Holden Cruze 1.4-litre turbo four-cylinder and even the Hyundai i45 (claimed as the first naturally-aspirated four-cylinder production car with the technology).

We can expect to see more and more cars coming out of the factories with direct injection over the next few years. We’re all for it, more horsepower and lower fuel consumption, what’s not to like?

Electronic fuel supply system for petrol engine giving the way to remove the carburetor, But even it has the throttle to cause the part load efficiency. I hope very soon we may replace this.

hi performancedrive.com.au-ers all the best to all of you – matty